Image 1 of 10

Image 1 of 10

Image 2 of 10

Image 2 of 10

Image 3 of 10

Image 3 of 10

Image 4 of 10

Image 4 of 10

Image 5 of 10

Image 5 of 10

Image 6 of 10

Image 6 of 10

Image 7 of 10

Image 7 of 10

Image 8 of 10

Image 8 of 10

Image 9 of 10

Image 9 of 10

Image 10 of 10

Image 10 of 10

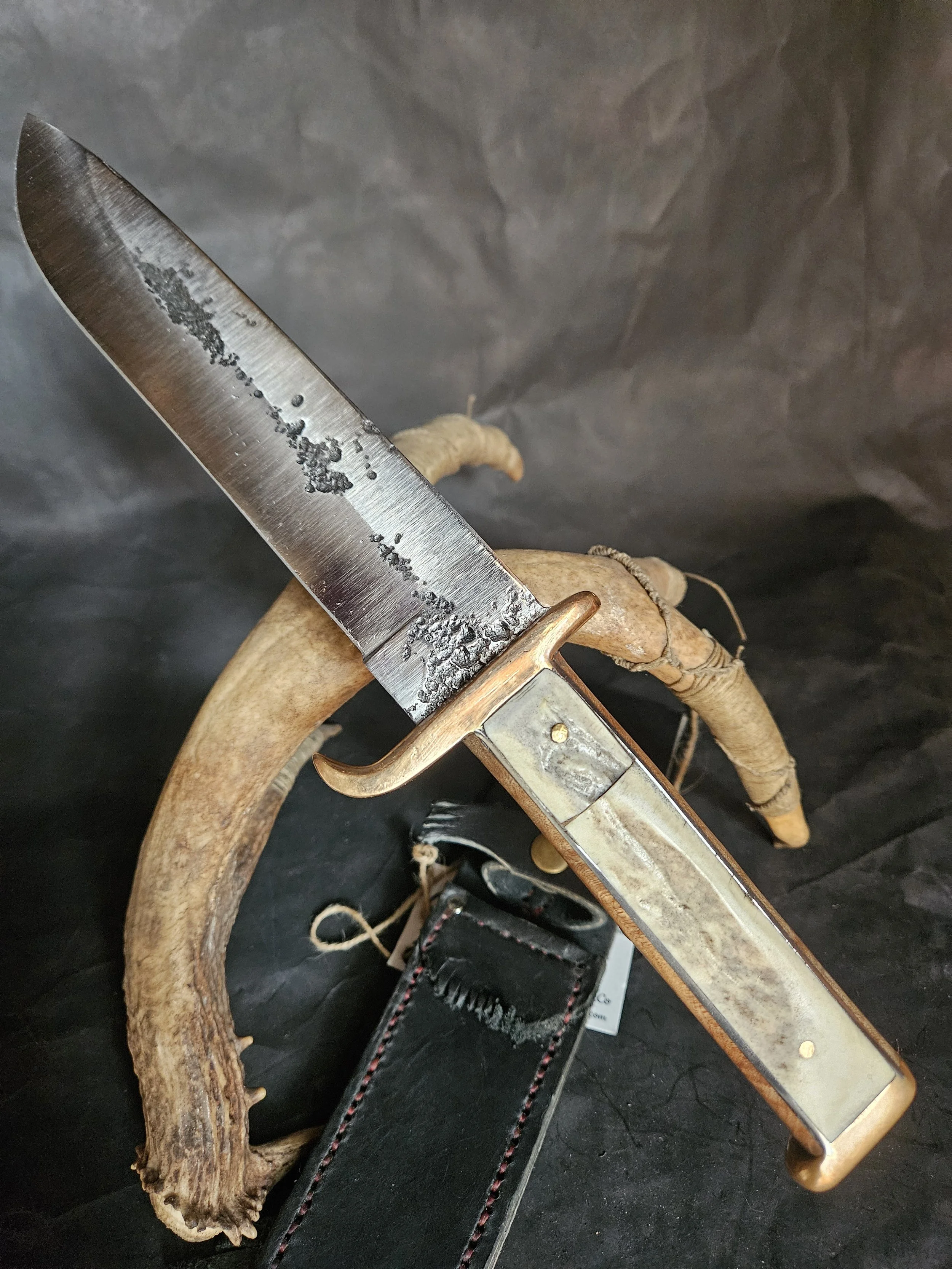

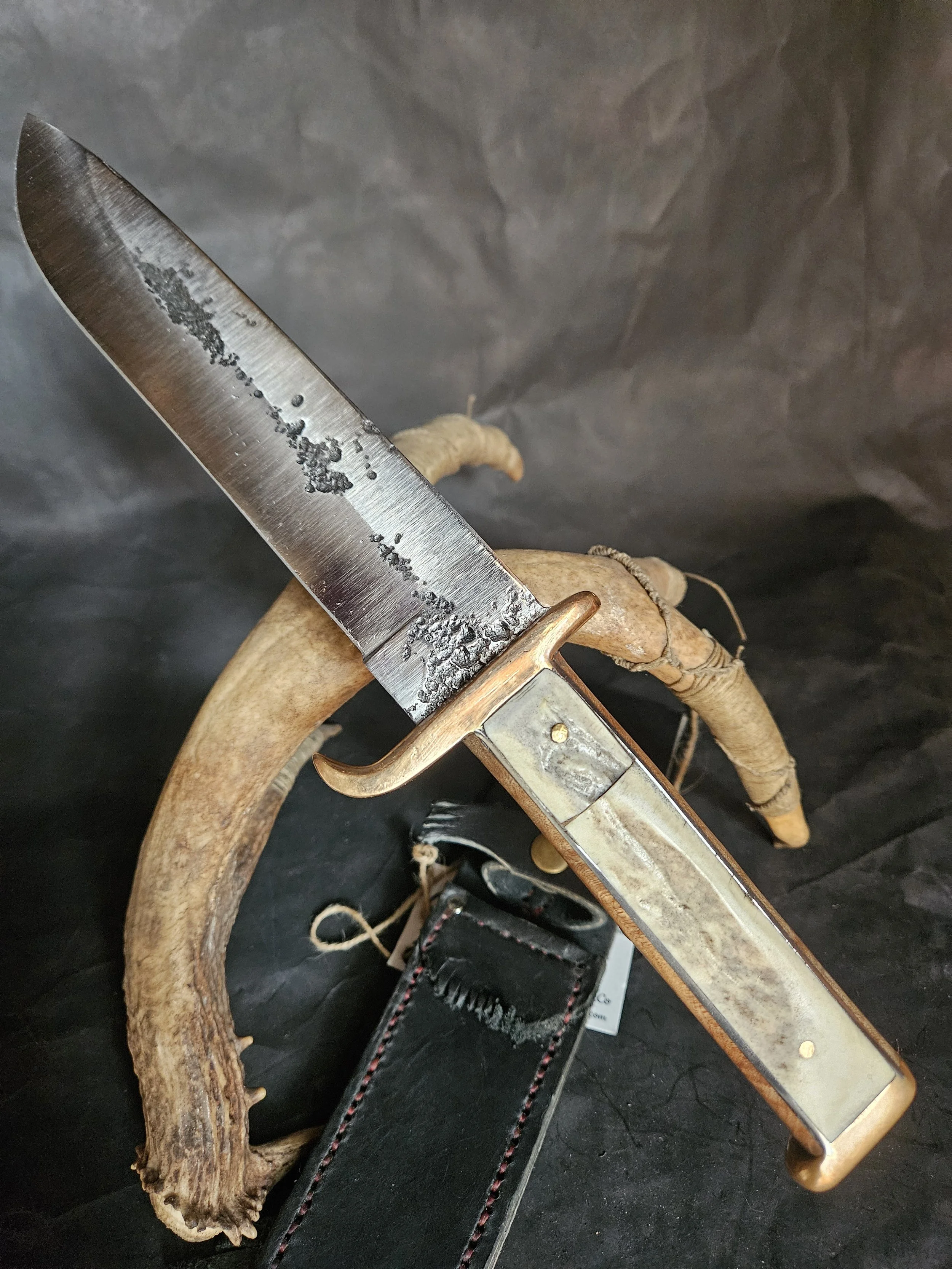

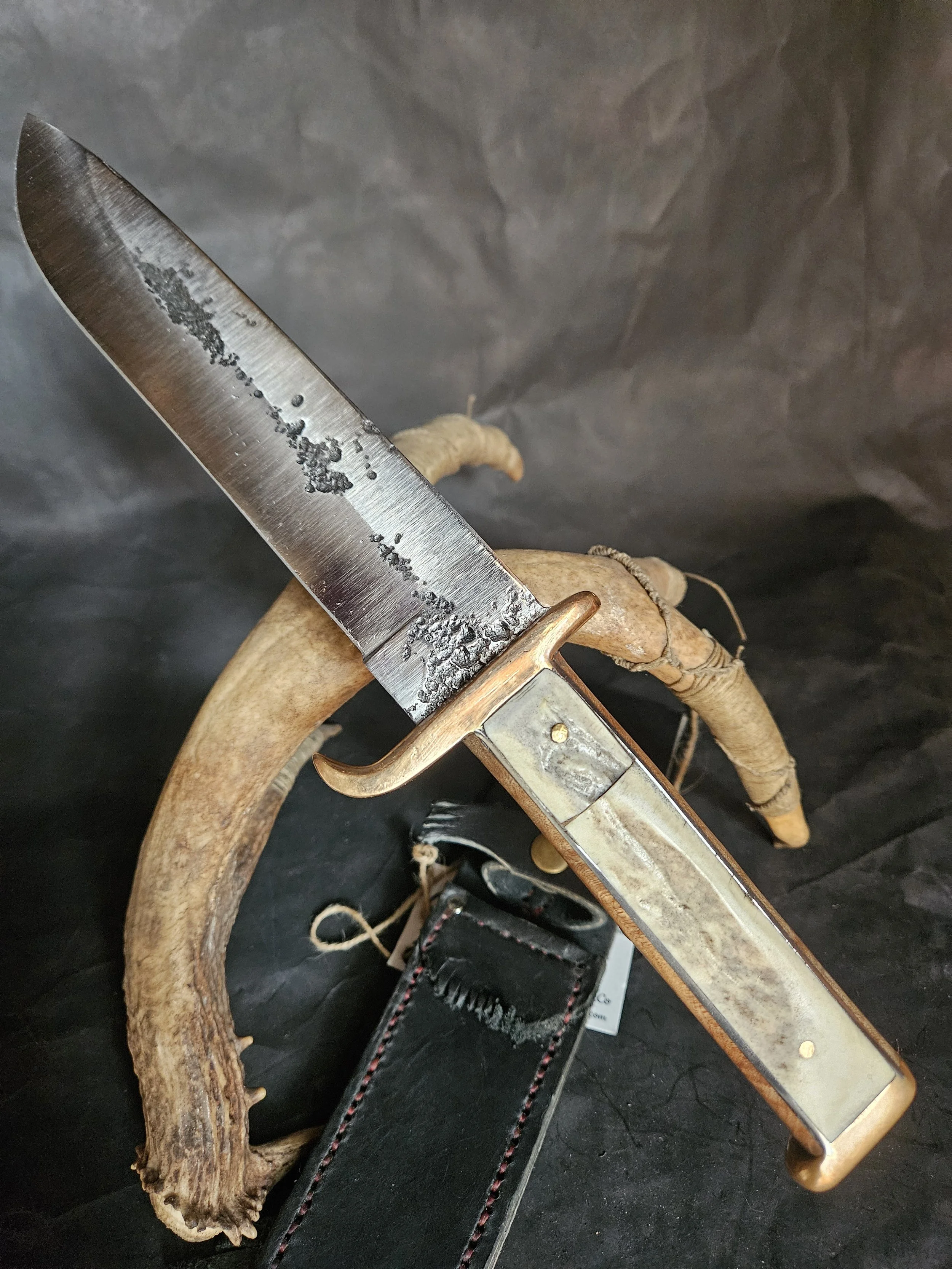

Fringed and Freaky Bowie Knife

I was working in the shop, and thinking about an old bicycle I used to own that had a brazed bi-plane style crown lug on the fork. It was a great bike that met an unfortunate end cause by my negligence, a missed stop sign and cross traffic.

The concept of using two thin pieces of steel separated by a web is what gives “I-beams” their impressive strength to weight ratio. I borrowed and bastardized that concept for this knife. Effectively it has two parallel tangs perpendicular to the blade. The 5160 steel blade passes through the copper guard and extends roughly an inch into the two thin pieces of steel. The blade, guard, and twin tangs are all brass brazed together then brazed into the copper pommel.

The blade itself is forged from reclaimed high carbon steel. It was sourced from the leaf springs of an old Hudson Motor Car Co vehicle my wife and I found in a river. The steel has deep pitting from spending the last 60-100 years in a river, and required substantial work in forge to remove the rust and contaminants. Conversely, I was careful to not over-work or over-finish the steel so some of it’s character can shine through. The result is a robust blade with a rock well hardness of roughly 60.

Moose Palm scales were fit over a stabilized wood core and pinned in place over the center of the handle. Top and bottom are stabilized figured maple scales with a single brass pin. The asymmetrical handle has a unique shape but fills the hand well.

The Black leather sheath is made chrome tanned leather. I exclusively source my new leather from Quil Ceda Leathery company, a local third generation tannery. It has red stiching and fringes along the point, where the knife is inserted and snap tab.

Sheathed length: 14-1/8’’

overall length: 12-7/8’’

blade length: 7-1/4’’

effective blade length: 6-7/16’’

blade thickness: 5/32’’

I was working in the shop, and thinking about an old bicycle I used to own that had a brazed bi-plane style crown lug on the fork. It was a great bike that met an unfortunate end cause by my negligence, a missed stop sign and cross traffic.

The concept of using two thin pieces of steel separated by a web is what gives “I-beams” their impressive strength to weight ratio. I borrowed and bastardized that concept for this knife. Effectively it has two parallel tangs perpendicular to the blade. The 5160 steel blade passes through the copper guard and extends roughly an inch into the two thin pieces of steel. The blade, guard, and twin tangs are all brass brazed together then brazed into the copper pommel.

The blade itself is forged from reclaimed high carbon steel. It was sourced from the leaf springs of an old Hudson Motor Car Co vehicle my wife and I found in a river. The steel has deep pitting from spending the last 60-100 years in a river, and required substantial work in forge to remove the rust and contaminants. Conversely, I was careful to not over-work or over-finish the steel so some of it’s character can shine through. The result is a robust blade with a rock well hardness of roughly 60.

Moose Palm scales were fit over a stabilized wood core and pinned in place over the center of the handle. Top and bottom are stabilized figured maple scales with a single brass pin. The asymmetrical handle has a unique shape but fills the hand well.

The Black leather sheath is made chrome tanned leather. I exclusively source my new leather from Quil Ceda Leathery company, a local third generation tannery. It has red stiching and fringes along the point, where the knife is inserted and snap tab.

Sheathed length: 14-1/8’’

overall length: 12-7/8’’

blade length: 7-1/4’’

effective blade length: 6-7/16’’

blade thickness: 5/32’’